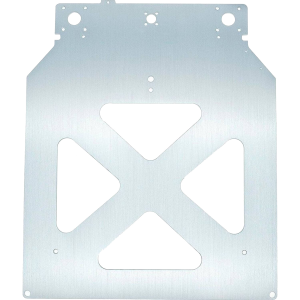

With the DaFlexpad system you can use the same print bed surface as the Ender 3 pro.

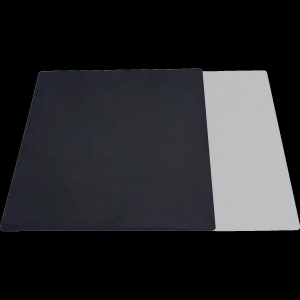

Our system consists of only two parts. A magnetic foil and a magnetic print bed foil.

Just like the original, we have also attached a tab to the front to make it easier to remove from the print bed.

How does it work?

Once the system is attached to your printer, you simply continue printing as usual. There are no restrictions. After the print is finished you can simply detach the print surface from the print bed and release your component by twisting the print bed foil. We generally recommend to let the print bed cool down a bit, so you don't burn your paws! In contrast to some ready-made systems, where neodymium magnets are embedded in the heating plate, here you have an absolutely even magnetic force that holds your Flexpad firmly. The advantage here is clearly in the production. We do not have to go the detour and glue the Flexpad first on a metal plate but can save this step completely. This also makes the system cheaper for you than comparable models.

Features:

- Set consisting of Flexpad and magnetic foil

- easy to attach

- Works with PLA and PETG

- Heating bed can still be used

- Easy replacement when more printing is needed

- Smaller unevennesses of the heating bed can be compensated

Mounting instructions:

1) Thoroughly clean and degrease the heating bed (remove any adhesive film beforehand)

2) Peel off the brown side of the adhesive film and apply it cleanly and free of bubbles

(If you first apply some rinsing solution, you can still slightly readjust the film and work out any bubbles with a squeegee)

3) Heat me up baby! Heat the heating bed to 50° and let the foil dry like this

4) You can now apply the Flexpad and start printing.

NOTE!

When printing PETG, it is mandatory to apply a "sacrificial layer" sacrificial layer. PETG has enormous adhesive forces and can damage many printing surfaces. We recommend applying a sacrificial layer by means of a glue stick before printing. The sacrificial layer does not reduce adhesion, but allows the component to be released without problems after cooling.

There are no reviews yet.